Grease filters

Parameters

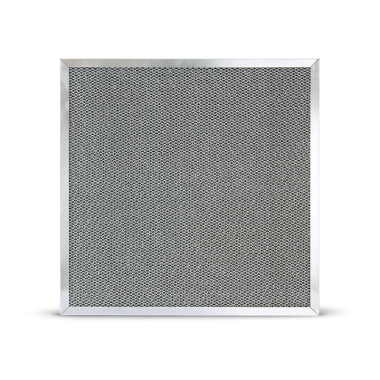

The aluminium mesh is inserted to the aluminium profile in several layers.

Input and output side of the filter is protected by aluminium expanded metal. At higher depths of the filter, the carrier core is inserted into the center of the filter.

The dimensions and depth of the filter specifies the customer. The depth of the filter is produced in the range from 8 mm to 150 mm.

For perfect function, it is necessary to keep the grease filters clean. When the filters are clogged, they need to be washed in hot water with the contents of active detergents or a solution of bicarbonate of soda.

If there is irreversible damage to the filters, we liquidate the filters in the collection of metal waste.

Use

We produce the grease filters in the aluminium design and they are intended mainly for the detection of fatty particles in the food industry. However, the filters installed in industrial plants--steel mills, welding metal plants, in areas with excessive amounts of oil aerosol. The filters also capture a stream of sparks when grinding and cutting of metal materials.

Filtration classes

- G2; ISO Coarse 40%

- G3; ISO Coarse 50%

Sizes

| Sizes in mm | m3/h | Pa | m2 |

|---|---|---|---|

| 287x592x25 | 1620 | 28 | 0,17 |

| 400x400x25 | 1520 | 28 | 0,16 |

| 400x500x25 | 1900 | 28 | 0,20 |

| 400x625x25 | 2350 | 28 | 0,25 |

| 500x500x25 | 2350 | 28 | 0,25 |

| 500x625x25 | 2950 | 28 | 0,32 |

| 592x592x25 | 3350 | 28 | 0,35 |

| 287x592x48 | 1620 | 48 | 0,17 |

| 400x400x48 | 1520 | 48 | 0,16 |

| 400x500x48 | 1900 | 48 | 0,20 |

| 400x625x48 | 2350 | 48 | 0,25 |

| 500x500x48 | 2350 | 48 | 0,25 |

| 500x625x48 | 2950 | 48 | 0,32 |

| 592x592x48 | 3350 | 48 | 0,35 |

EN

EN

CZ

CZ

NJ

NJ