Z-LINE ePM10 80 % (F7)

EN ISO 16890

(formerly EN 779:2012)

The filters are primarily used as pre-filters or main filters, depending on the respective filtration class.

Product Description

Carton and plastic frame:

Into the frame made of hardened paper (carton) or plastic is embedded a filter media component made of synthetic material of the required filtration class. The composite is then sealed with hot melt adhesive. The filter inlet and outlet are fitted with a paper grid. The direction of air flow is indicated by an arrow on the filter frame. The filters in paper and plastic frames are manufactured in depths of 20, 25, 48 and 96 mm. The width and height of the frame is optional.

After the filters are clogged, they are completely replaced with new filters. Used filters are disposed of in incinerators or controlled landfills.

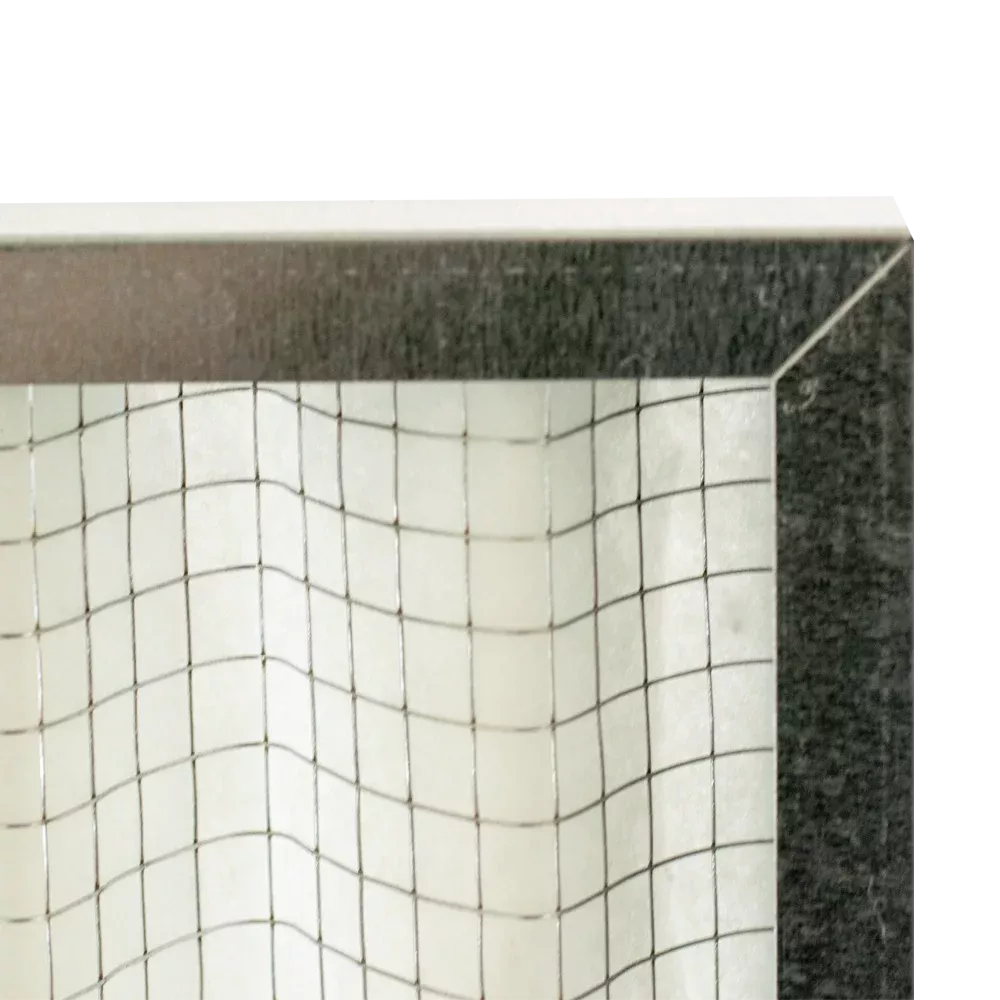

Plastic and metal frame:

In the case of filters mounted in plastic or metal frames, the filter media of the required filtration class is deposited on a corrugated support grid. The direction of air flow is shown by an arrow on the frame. In the case of metal frames, the filter depth can be agreed individually. To restore the function of the filter, after removing the clogged filter media, the frame must be wiped clean and new filter media inserted. If the frames are deformed, the entire filter is replaced.

Used filters are disposed of in incinerators or can be stored in controlled landfills.

Technical data

Filtration class EN 779:2012: F7

EN ISO 16890: ePM10 80 %

End pressure drop: 250 Pa

Operating temperature: 80 °C, 100 °C