Pocket filter ePM2,5 65 % (F7)

EN ISO 16890

(formerly EN 779:2012)

In areas with increased risk of explosion, paint shops, chemical and rubber industries and ammunition production.

Description

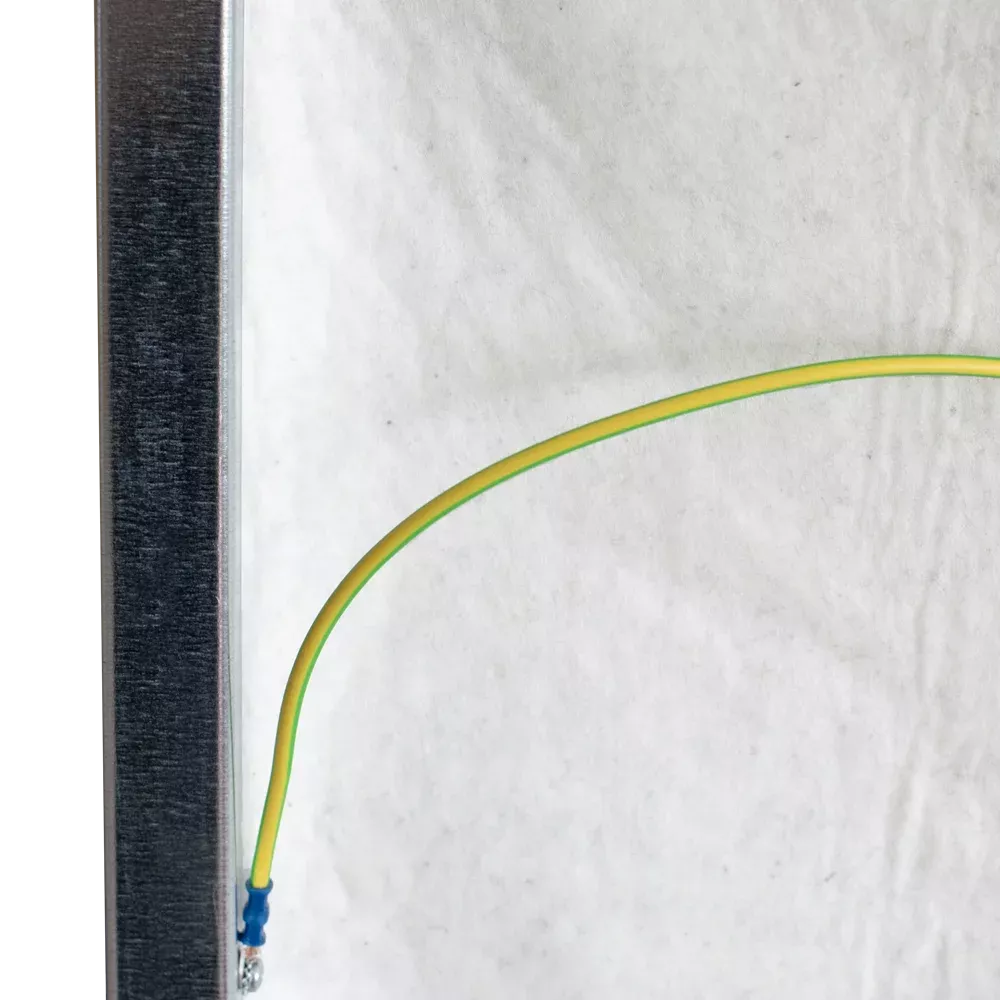

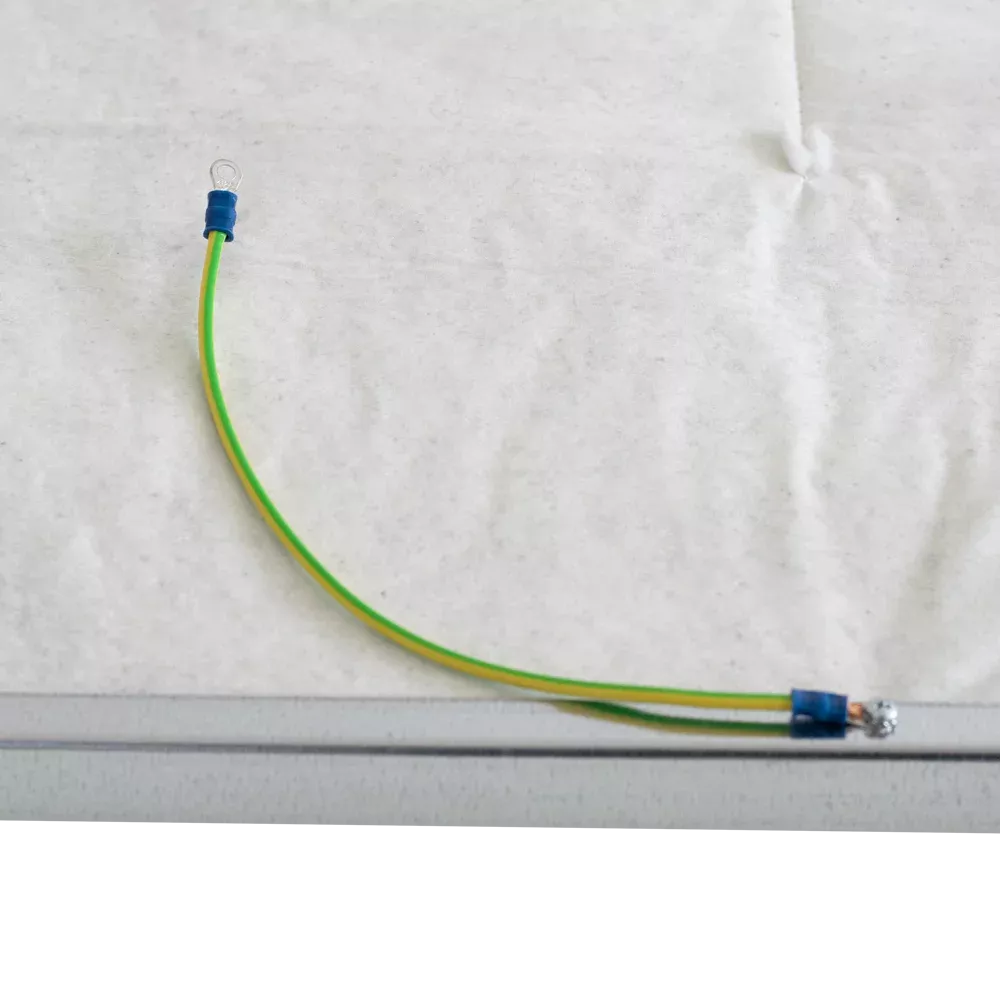

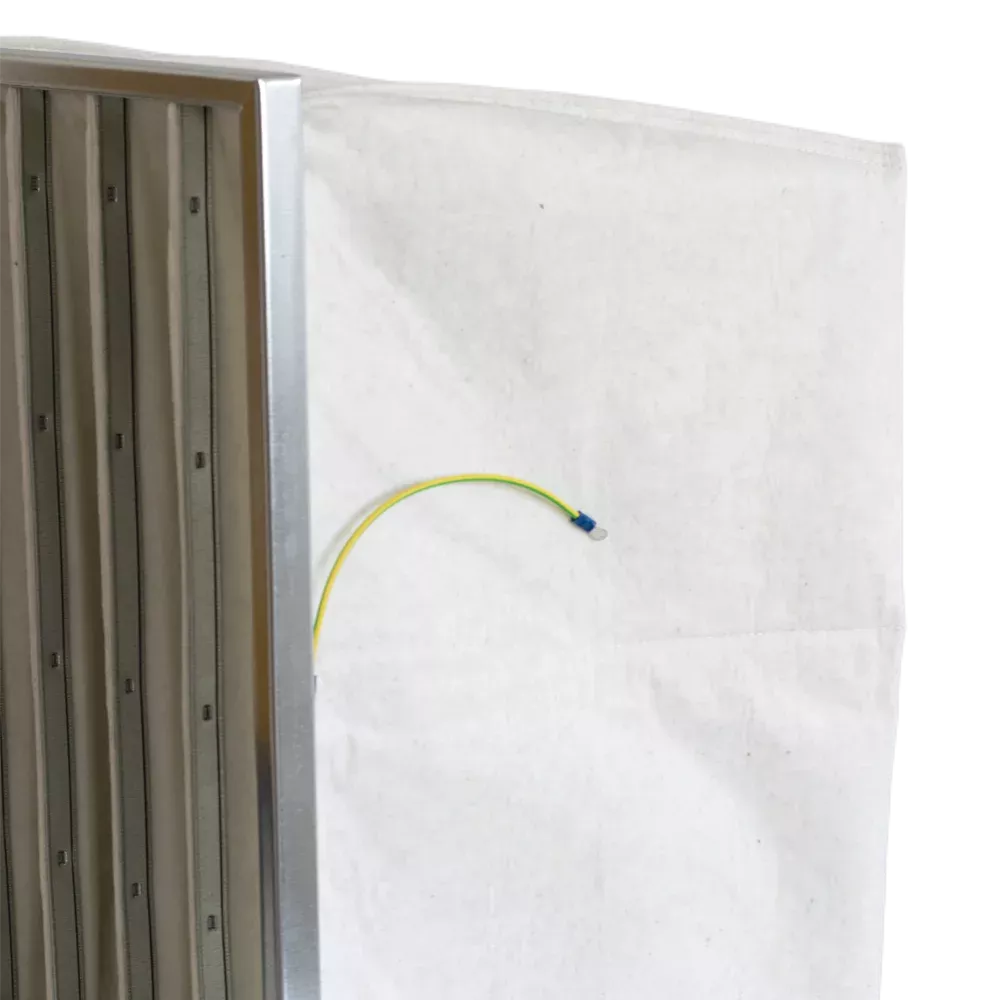

The pocket filters in antistatic design are made of a special electrostatically conductive filter medium. The processing of the material is carried out as standard on the KSL automated sewing centre, which ensures the pockets' conicity. The individual pockets are then inserted into galvanized steel frames fitted with a grounding clamp in the form of an approx. 30 cm grounding cable with an eyelet.

The pocket filters in antistatic design are manufactured as standard in classes M5 (ISO ePM10 50%) and F7 (ISO ePM2.5 65%). The filters meet the requirements for use in hazardous areas zone 2, zone 1, zone 0 (EN 1127-1) with gases and vapours of explosion subgroups IIA, IIB, IIC (EN 50014) and in hazardous areas with dust explosion zone 22, zone 21 and zone 20 (EN 1127-1). The filters are therefore mainly used in paint shops, chemical plants, rubber industry, munitions production, etc. Maximum heat resistance of the filter up to 150 °C.

Please consult the manufacturer for any requirements for filters with other filter classes.

In addition to standardized dimensions, we also produce pocket filters in atypical dimensions.

Technical data

Filtration class: EN 779:2012: F7

EN ISO 16890: ePM2,5 65 %

Initial pressure loss: 100 Pa

Final pressure loss: 300 Pa

Operating temperature: do 150 °C

Nominal air flow: 3400 m3/h