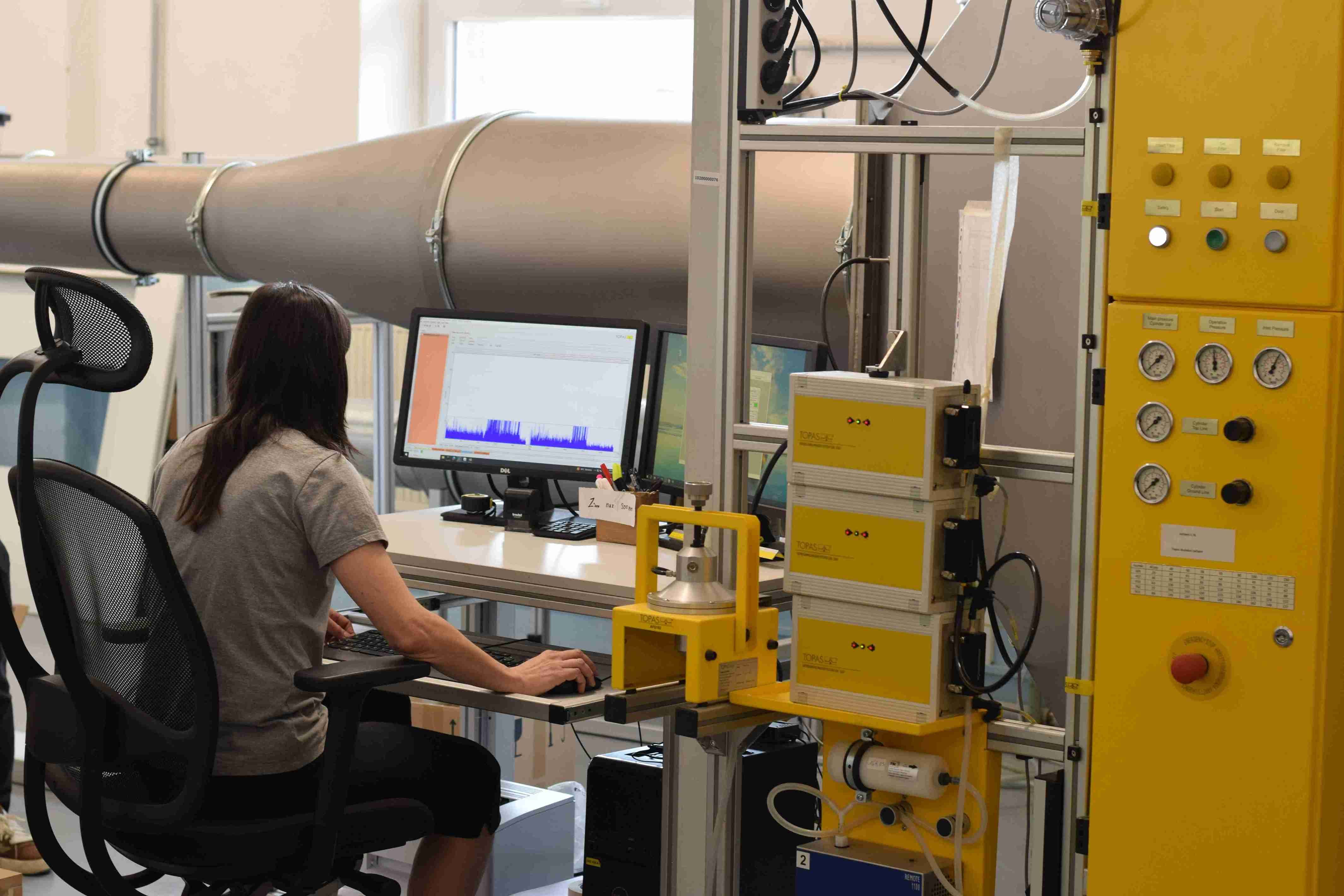

Filter testing laboratory

To determine the tightness, efficiency, and pressure drop, all high-efficiency filter elements (E12, H13, H14, and U15) are subjected to a SCAN test according to ISO 29463.

The SCAN test of filters is an important procedure used to verify the quality and performance of the filters.

During the SCAN test, a defined amount of microscopic particles is introduced into the filter, and the entire filtration surface is scanned. This test assesses the local filtration efficiency at each point of the filter under conditions of the most penetrating particle size (MPPS) and compares the results with the minimum local efficiency values specified by the standard.

Areas with lower efficiency are considered leaks. After resealing, the filter undergoes a new SCAN test. From the integrated local values, the total efficiency of the filter element is calculated.

The result of the SCAN test is a certificate confirming the capture efficiency without local defects, along with the measured pressure drop at the given flow rate. This certificate has its own serial number, which is also printed on the filter’s label.

Filter elements in lower filtration classes or in special designs and dimensions that cannot be scanned are tested for defects using the so-called string (or strand) method with oil mist.